Higuchi Quartz custom lamp: We can produce all types of custom Quartz lamps in Non-ozone 254nm, Ozone, and reduced ozone spliced lamps. These lamps can be modified to various sizes, output and with custom base designs.

Higuchi Standard lamp: We can supply all types of Soft glass lamps, considered the standard workhorse lamp and economical. These lamps are similar to Fluorescent lamp design such as those produced by Philips & GE. Made in Japan

Services: Lamp performance verification: We will take measurement of electrical characteristic, UVC & Ozone output, Output depreciation over life, and these data in comparison with your current lamp vs our lamp for comparative purposes.

Ballast matching: We will take measurement of UVC output between different ballast options and analyze Lamp current so you can select the most optimised lamp & ballast combination.

Troubleshooting: If you are having quality or service issues with your current lamp supplier, we can analyze the problem to find better solutions for you. —Known issues such as – blackening, sputtering, short life, filament breakage, overall lamp construction, soldering, supplier lead time, supplier inability to correct disputes. Higuchi provides quality assurances with the product expectation, lead time promise, financial stability, mutual resolution of disputes. We value long term business relationship

BLOOD PURIFICATION

Result: longer service life for lamps.

Challenge: This application required using 24 lamps in close proximity and for those lamps to be turned on/off every 15 seconds causing excessive stress on the filaments. This type of use can have negative impact on the lamp in several ways. (1) every time the lamp is turned on, an emitter coating on the filament is dispersed off the tungsten wire due to the electrical pulse upon ignition. When the emitter coating eventually is spent, the lamp will cease to turn on. (2) the dispersal of the emitter material also creates a blacking layer on the inside of the glass, filtering the UV output, resulting in decreased output. When frequently turning the lamp on & off with short cycling, it is important keep the filament pre-heated at a certain temperature to reduce the electrical shock the filament has to endure when igniting. Cold start is not recommended, and the laboratory test condition for lamp cycling is 2hrs 45min ON & 15min OFF(3hr cycling). Cycling under this time will reduce lamp life.

Solution: recommendation of preheat circuit for constant glow start of the lamps. Use of Anode guard for the filament to absorb the emitter coating and prevent blackening.

HEARING AID SANITIZER

Result: Seamless delivery, production and accounting.

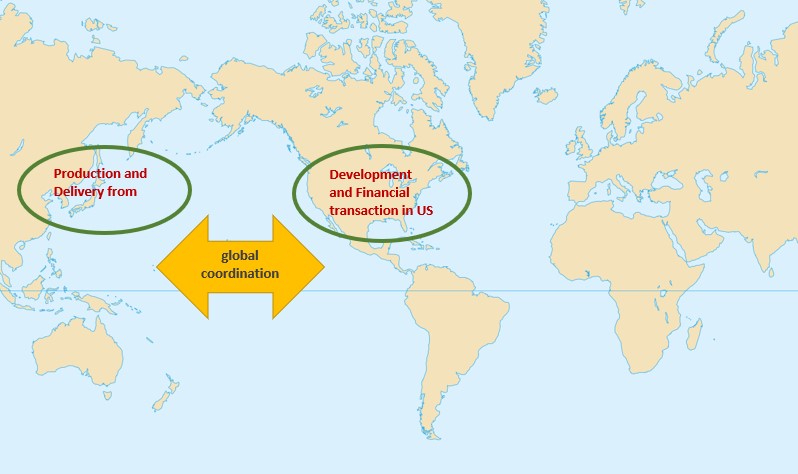

Challenge: Hearing aids are expensive to repair, and often malfunction due to humidity and bacterial growth. There was worldwide demand for a Hearing aid UV disinfection system, and required the manufacturer to produce the disinfection box in cost effective SE Asia factories, while the development & management was HQ in the USA

Solution: To manage the UV lamp supply chain coordination with the US administrative office, the 3rd party mold and assembly plant in SE Asia, and our UV lamp factory in Japan. Our team members are located in Japan, China and the USA. We can efficiently deliver our UV lamps to any 3rd party production facilities around the world, while taking care of logistics and financial matters directly with your main corporate office.

SHOE DISINFECTION DEVICE

Result: Effective yet small package delivery of UVC irradiation

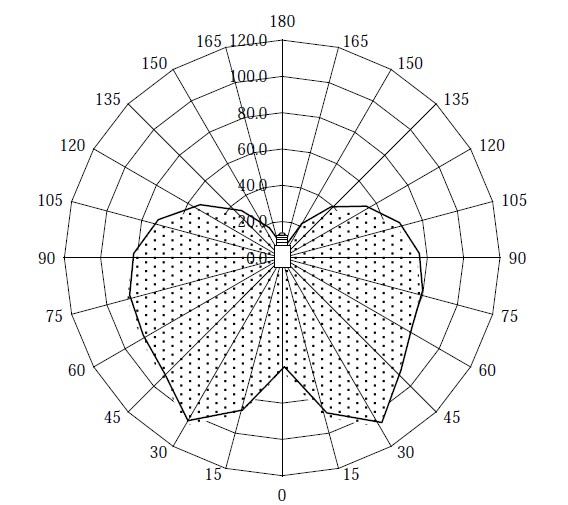

Challenge: to develop a small yet robust UV disinfection device to fit inside the tip of an shoe to disinfect and treat odor and infection causing bacteria & fungus. Typical UV lamps are tubular and has connection on both ends of the tube, making the device too large and preventing efficient UV irradiation pattern inside the shoe.

Solution: Development of an miniature bulb type UV lamp with 270 degree irradiatoin pattern to enable UVC ray to reach the tip of the shoe.

HVAC UVC COIL DISINFECTION

Result: This robust and reliable HVAC UVC air and coil cleaner is still the industry leader for residential and small commercial UV systems.

Challenge: We are one of the first UV lamp manufacturers to help launch an HVAC UVC Coil disinfection product in the USA. Most of the available lamps were low wattage UV lamps, limited in UV output.

Solution: We helped design a high output single ended UV lamp to increase the available UV output within a limited space by increasing the overall UV power & Arc length.

AIR STREAM DISINFECTION

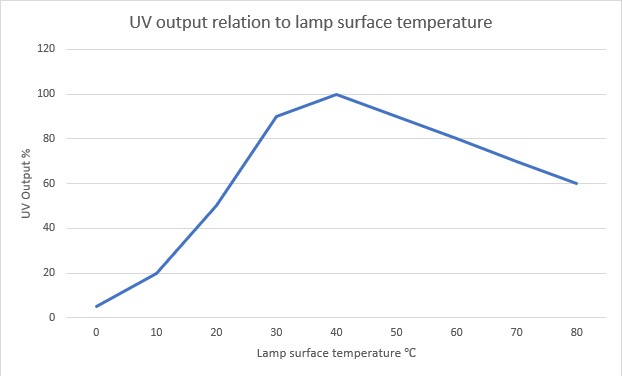

Result: We were able to quantify the UV output at various temperature range to show which temperature setting was the best for each individual lamp design and application, to help you obtain the highest UV output by optimizing the lamp temperature or choosing the correct Ballast output.

Challenge: A customer was not able to achieve UVC output at the specified value in the air stream.

Solution: Our engineer made a prototype UV lamp and measured the UVC output side by side using the customer supplied Ballast. We found out that the lamp Current was too high for its Length and Diameter, causing the lamp to overheat. UVC output decreases when the lamp is operating too cold or too hot.

CONSULTING & SUPPORT

Result: Increase in production efficiency, management flow and bottom line profitability. Additionally, product warranty is offered in the US, therefore in the case of re-production or refund, there is no need to negotiate recovery with overseas agents.

Challenge: Running out of stock: One customer had delivery issues from their supplier and could not get lamps on the promised date, resulting in loss of business, idle production line and loss of trust from their customers. These failed deliveries have become a common issue with recent disruptions throughout the supply chain.

Solution: We consult with customers production management to find out the production flow and schedules, find out the best delivery method, create production schedule to meet on time delivery, carry extra inventory, and increase our factory production capacity in order to meet customer schedule demands in a multi discipline method.